- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Grafit de specialitate Producători, Furnizori, Fabrică

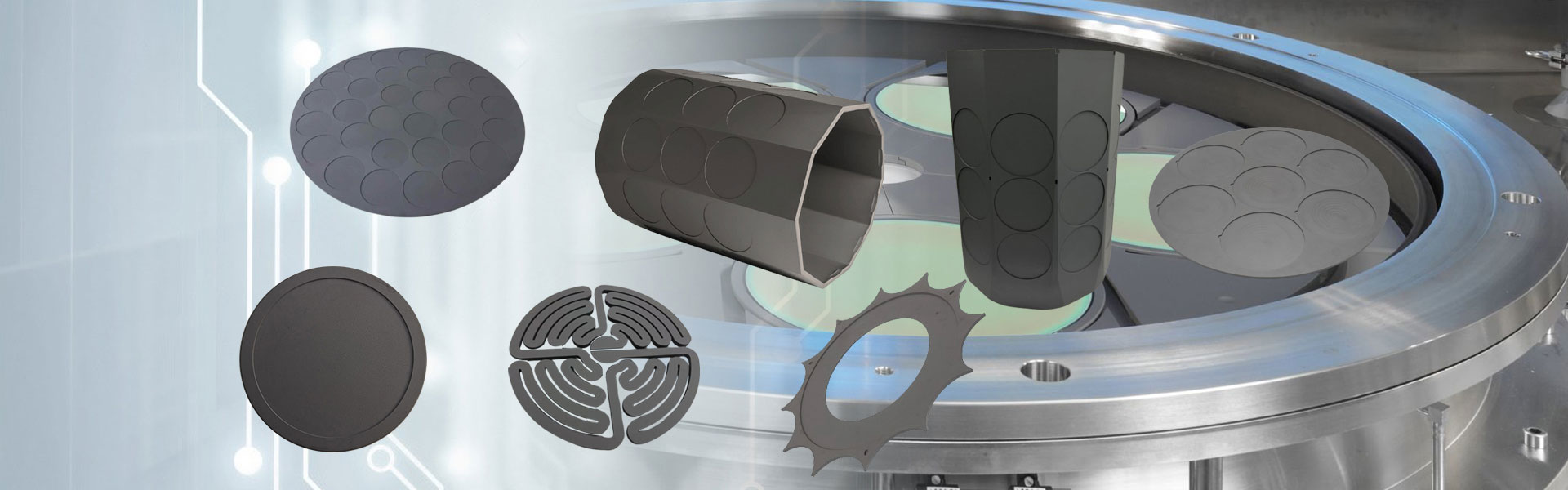

Speciality Graphite este un fel de grafit artificial care este procesat. Este un material important care este indispensabil în toate aspectele procesului de fabricație semiconductor și fotovoltaic, inclusiv creșterea cristalului, implantarea ionilor, epitaxia etc.

1. Creșterea cristalelor din carbură de siliciu (sic)

Carbura de siliciu, ca material semiconductor de a treia generație, este utilizat pe scară largă în vehicule energetice noi, comunicații 5G și alte câmpuri. În procesul de creștere a cristalelor SIC de 6 inci și 8 inci, grafitul izostatic este utilizat în principal pentru fabricarea următoarelor componente cheie:

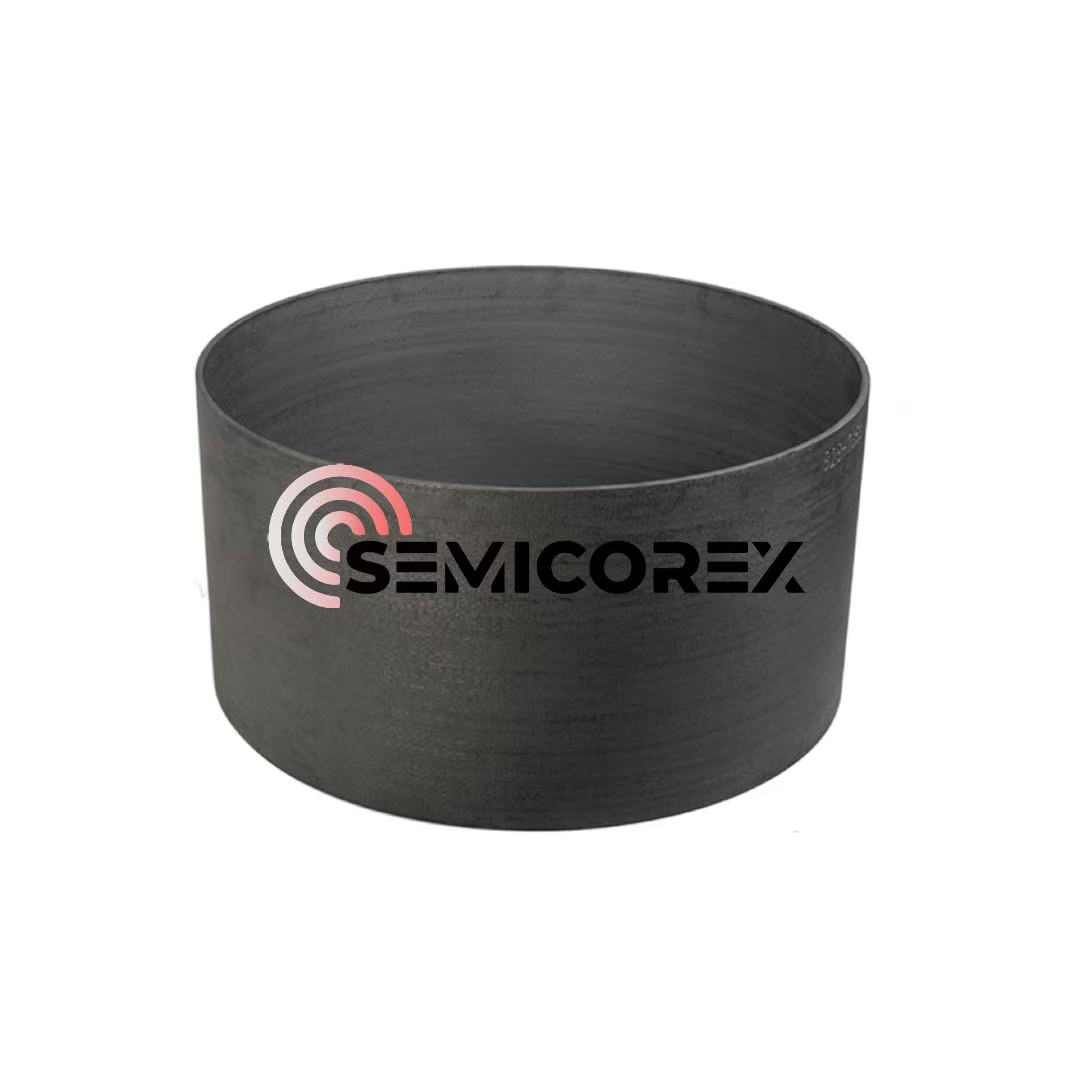

Crucible de grafit: Acest lucru poate fi utilizat pentru a sintetiza materiile prime de pulbere SIC și, de asemenea, ajută la creșterea cristalului la temperaturi ridicate. Puritatea sa ridicată, rezistența la temperatură ridicată și rezistența la șoc termic asigură un mediu stabil de creștere a cristalelor.

Încălzitor de grafit: Aceasta oferă o distribuție uniformă a căldurii, asigurând o creștere a cristalului SIC de înaltă calitate.

Tub de izolare: Aceasta menține uniformitatea temperaturii în cadrul cuptorului de creștere a cristalului și reduce pierderea de căldură.

2. Implantare ionică

Implantarea ionică este un proces cheie în fabricarea semiconductorilor. Grafitul izostatic este utilizat în primul rând pentru a fabrica următoarele componente în implantele ionice:

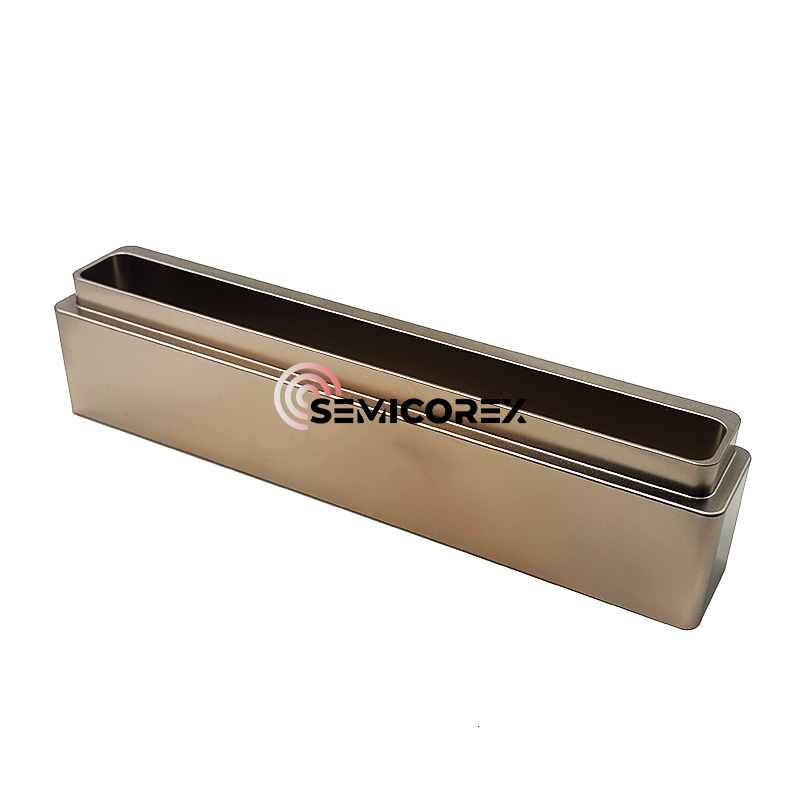

Graphite Getter: Aceasta absoarbe ioni de impuritate în fasciculul ionic, asigurând puritatea ionului.

Inel de focalizare a grafitului: acest lucru focalizează fasciculul ionic, îmbunătățind precizia și eficiența implantului ionic. Tăvi de substrat de grafit: utilizate pentru a susține napolitane de siliciu și pentru a menține stabilitatea și consistența în timpul implantării ionice.

3. Procesul de epitaxie

Procesul de epitaxie este un pas critic în fabricarea dispozitivelor semiconductoare. Grafitul presat izostatic este utilizat în principal pentru a fabrica următoarele componente în cuptoarele de epitaxie:

Tăvi și susceptitori de grafit: utilizate pentru a sprijini napolitane de siliciu, oferind suport stabil și o conducere uniformă de căldură în timpul procesului de epitaxie.

4. Alte aplicații de fabricație a semiconductorilor

Grafitul presat izostatic este, de asemenea, utilizat pe scară largă în următoarele aplicații de fabricație semiconductoare:

Proces de gravură: utilizat pentru fabricarea electrozilor de grafit și a componentelor de protecție pentru gravuri. Rezistența sa la coroziune și puritatea ridicată asigură stabilitatea și precizia în procesul de gravare.

Depunerea de vapori chimici (CVD): folosită pentru fabricarea tăvilor și încălzitoarelor de grafit în cadrul cuptoarelor CVD. Conductivitatea sa termică ridicată și rezistența la temperatură ridicată asigură depunerea uniformă a filmului subțire.

Testarea ambalajelor: utilizată pentru fabricarea corpurilor de testare și a tăvilor de transport. Precizia sa ridicată și contaminarea scăzută asigură rezultate exacte ale testelor.

Avantajele pieselor de grafit

Puritate mare:

Folosind un material de grafit presat izostatic cu un conținut de impuritate extrem de scăzute, acesta îndeplinește cerințele stricte de puritate a materialelor din fabricarea semiconductorilor. Cuptorul de purificare al companiei poate purifica grafitul până sub 5 ppm.

Precizie ridicată:

Cu echipamente avansate de procesare și tehnologie de procesare matură, se asigură că precizia dimensională a produsului și toleranțele de formare și poziție ating nivelul micronului.

Performanță ridicată:

Produsul are o rezistență excelentă la temperatură ridicată, rezistență la coroziune, rezistență la radiații, conductivitate termică ridicată și alte proprietăți, care îndeplinesc diferitele condiții dure de muncă ale fabricației semiconductorilor.

Serviciu personalizat:

Serviciile personalizate de proiectare și procesare a produselor pot fi furnizate în funcție de nevoile clienților de a răspunde nevoilor diferitelor scenarii de aplicații.

Tipuri de produse grafit

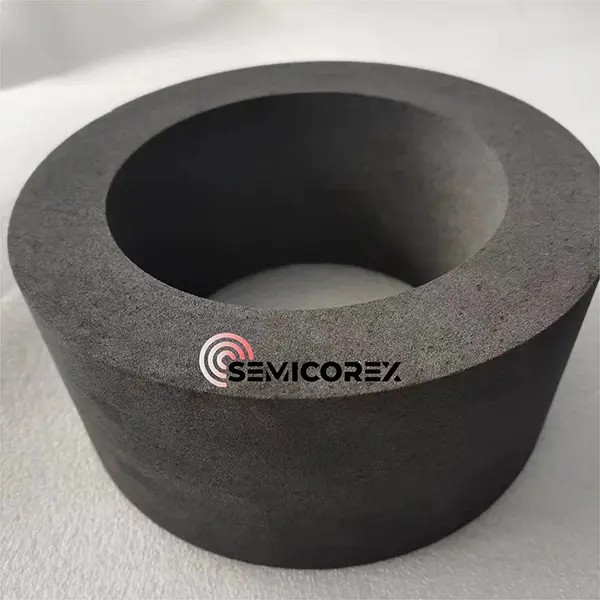

(1) Grafit izostatic

Produsele izostatice de grafit sunt produse prin presare izostatică rece. În comparație cu alte metode de formare, creuzetele produse de acest proces au o stabilitate excelentă. Produsele de grafit necesare pentru cristalele unice SIC au dimensiuni mari, ceea ce va duce la o puritate inegală la suprafață și în interiorul produselor de grafit, care nu pot îndeplini cerințele de utilizare. Pentru a îndeplini cerințele de purificare profundă a produselor de grafit de dimensiuni mari necesare pentru cristale unice SIC, ar trebui adoptat un proces unic de purificare a pulsului termochimic la temperatură înaltă pentru a obține o purificare profundă și uniformă a produselor de grafit de dimensiuni mari sau în formă specială, astfel încât puritatea suprafeței produsului și a miezului să îndeplinească cerințele de utilizare.

(2) Grafit poros

Grafitul poros este un tip de grafit cu porozitate ridicată și densitate mică. În procesul de creștere a cristalului SIC, grafitul poros joacă un rol semnificativ în îmbunătățirea uniformității de transfer de masă, reducerea ratei de apariție a schimbării fazelor și îmbunătățirea formei cristalului.

Utilizarea grafitului poros îmbunătățește uniformitatea temperaturii și temperaturii a zonei materiei prime, crește diferența de temperatură axială în creuzet și are, de asemenea, un anumit efect asupra slăbirii recristalizării suprafeței materiei prime; În camera de creștere, grafitul poros îmbunătățește stabilitatea fluxului de materiale pe parcursul procesului de creștere, crește raportul C/SI al zonei de creștere, ajută la reducerea probabilității de schimbare a fazelor și, în același timp, grafitul poros joacă și un rol în îmbunătățirea interfeței de cristal.

(3) simțit

Felt moale și pâslă tare, ambele joacă rolul materialelor de izolare termică importante în creșterea cristalelor SIC și legăturile epitaxiale.

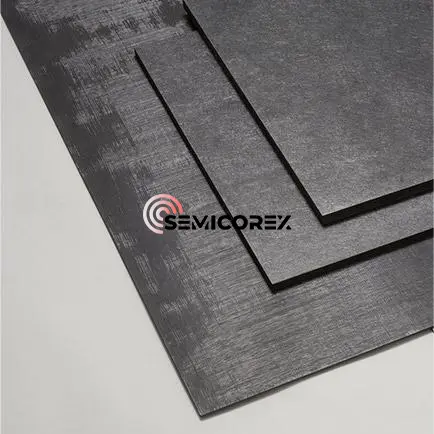

(4) folie de grafit

Hârtia de grafit este un material funcțional fabricat din grafit de fulg cu carbon ridicat prin tratament chimic și rulare la temperaturi ridicate. Are o conductivitate termică ridicată, conductivitate electrică, flexibilitate și rezistență la coroziune.

(5) Materiale compozite

Câmpul termic cu carbon carbon este unul dintre consumabilele de bază ale producției fotovoltaice cu un singur cristal.

Producție de semicorex

Semicorex face grafit cu metode de producție personalizate cu lot mic. Producția cu loturi mici face ca produsele să fie mai controlabile. Întregul proces este controlat de controlerele logice programabile (PLC), datele de proces detaliate au fost înregistrate, permițând trasabilitatea completă a ciclului de viață.

Pe parcursul întregului proces de prăjire, consistența obținută în rezistivitate în diferite locații și a menținut controlul strâmt al temperaturii. Acest lucru asigură omogenitatea și fiabilitatea materialelor de grafit.

Semicorex utilizează o tehnologie de presare complet izostatică, care este diferită de alți furnizori; Înseamnă că grafitul este în sine ultra uniform și este dovedit deosebit de important în procesele epitaxiale. Au fost efectuate teste de uniformitate a materialului complet, inclusiv densitate, rezistivitate, duritate, rezistență la îndoire și rezistență pe diferite probe.

- View as

Creuzete din grafit acoperite cu SiC

Crezetele din grafit acoperite cu SiC sunt recipiente esențiale prelucrate cu precizie din material grafit acoperit cu carbură de siliciu, oferind o rezistență excelentă la temperaturi ridicate și rezistență la coroziune chimică. Cu performanța lor superioară și calitatea fiabilă, creuzetele de grafit acoperite cu SiC de la Semicorex sunt soluția optimă pentru a obține o producție controlată de cristale de înaltă calitate.

Citeşte mai multTrimite o anchetăCilindri termoizolant C/C

Cilindrii termoizolant C/C sunt componentele termoizolante de înaltă performanță utilizate în sistemul de câmp termic pentru creșterea siliciului monocristal, servind atât funcțiile de izolare termică, cât și de suport. Cu performanțe excepționale de izolare termică, rezistență structurală excelentă și preț competitiv, cilindrii de izolare termică Semicorex C/C reprezintă opțiunea ideală pentru procesele dumneavoastră de creștere a cristalelor de înaltă calitate.

Citeşte mai multTrimite o anchetăÎncălzitoare compozite C/C

Încălzitoarele compozite C/C sunt componente avansate de încălzire realizate din compozite carbon-carbon de înaltă performanță, concepute special pentru utilizarea în cuptoare de înaltă temperatură. Servind drept piese cruciale în industria semiconductoarelor, încălzitoarele compozite C/C pot oferi o încălzire precisă și uniformă necesară pentru condiții optime de creștere a cristalelor.

Citeşte mai multTrimite o anchetăSuporturi pentru creuzete din compozit C/C

Suporturile creuzetelor din compozit Semicorex C/C sunt componentele compozite carbon-carbon fabricate cu precizie, care sunt special adaptate pentru a satisface cerințele riguroase ale condițiilor de temperatură ridicată. Ele sunt de obicei poziționate în partea de jos a creuzetului și sunt soluții de sprijin de încredere pentru stabilizarea creuzetului în cuptoarele de creștere a cristalelor la temperatură înaltă.

Citeşte mai multTrimite o anchetăGhidaj de curgere compozit carbon-carbon

Ghidajele de curgere compozite carbon-carbon sunt componentele semiconductoare cilindrice avansate, servind drept soluții geniale pentru a garanta fabricarea cu succes a siliciului monocristal în sistemele de tragere la temperatură înaltă. Ele pot servi atât ca directori de flux de gaz, cât și ca izolatori termici în timpul producției de siliciu monocristal la temperatură ridicată.

Citeşte mai multTrimite o anchetăTije de grafit impregnate

Tijele de grafit impregnat Semicorex sunt prelucrate pretios, sunt realizate din grafit impregnat de inalta calitate, utilizat pe scara larga in industria mecanica. Semicorex este o companie de top din China care furnizează produse din grafit de înaltă calitate.*

Citeşte mai multTrimite o anchetă